Table of Contents

ToggleHonda V3 Engine

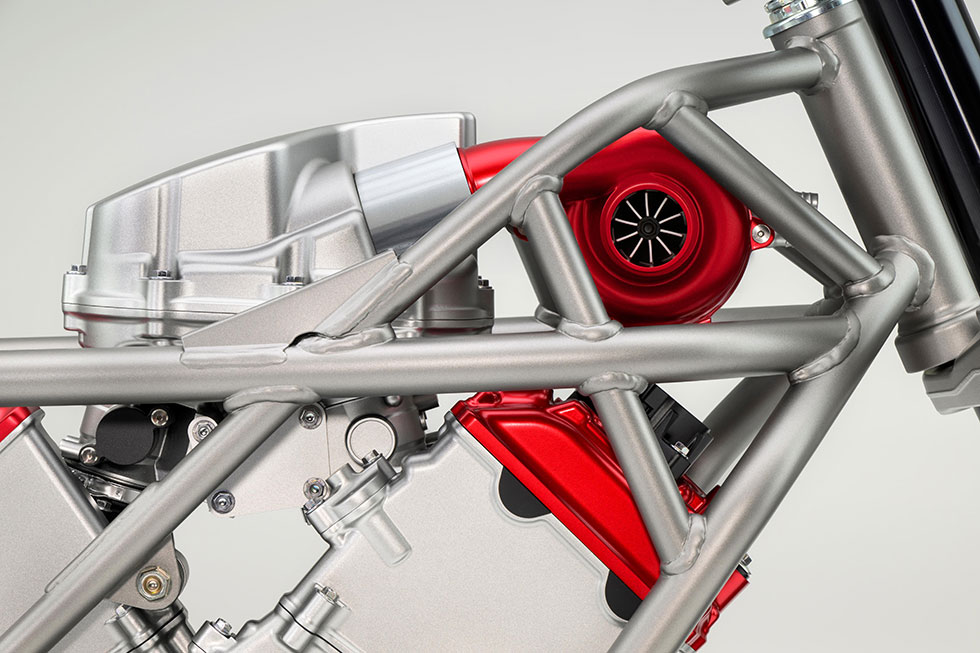

Honda has just introduced an exciting new 75-degree Honda V3 engine for larger-displacement motorcycles, designed to be both compact and high-performing. I find it fascinating that they’ve crafted this water-cooled engine to deliver high torque even at lower revs, using an electric compressor to control intake air compression independently of engine speed. This means an immediate torque response, no matter the RPM.

The layout of the engine is interesting as well, with two cylinders in the forward bank and one cylinder towards the rear. This setup, along with the electric compressor, allows for a compact design that’s crucial for motorcycles where space is at a premium. By prioritizing mass centralization, Honda’s engineers are optimizing balance and handling, while skipping the need for an intercooler, which also conserves space.

Honda promises that this Honda V3 engine will offer a smooth, responsive ride. It’s part of their broader goal to appeal to all kinds of riders—from daily commuters to those seeking high performance. We can expect to see this innovative engine in larger Honda models soon, with plans for mass production on the horizon.

Also read The All-New 2024 Honda H’ness CB350 A Modern Classic with Timeless Appeal

How Honda V3 Engine Works?

The innovative mechanism behind Honda’s new 75-degree V3 engine with an electric compressor involves several key engineering elements designed to boost performance while keeping the engine compact.

75-Degree V3 Layout

The Honda V3 engine configuration means there are three cylinders arranged in a V-shaped configuration with a 75-degree angle between the two cylinder banks. Honda has chosen an unconventional layout here two cylinders are positioned in the forward bank, and one is positioned in the rear. This configuration helps reduce the engine’s physical footprint, keeping it more compact for better balance and handling on a motorcycle.

Electric Compressor

An electric compressor, often called an e-compressor or electric turbo, works by compressing the intake air using electric power instead of relying solely on engine speed. Traditional turbochargers or superchargers typically depend on exhaust gases or the engine’s power, respectively, to spin a turbine and increase air intake. However, with an electric compressor, the intake air can be compressed independently of engine speed, which means it doesn’t have to wait for the engine to reach high RPMs to generate torque.

This technology is especially valuable for motorcycles, as it allows the engine to deliver immediate torque regardless of the RPM. Essentially, as soon as you twist the throttle, the electric compressor kicks in to provide the extra intake air, boosting low-end torque and giving quick, responsive acceleration.

Optimized Airflow and Response

Because the electric compressor is independent of engine speed, it can respond instantly when the rider accelerates. This makes for smooth power delivery without the lag typically associated with traditional turbochargers that rely on exhaust gas pressure to build up.

Additionally, since it’s not tied directly to the engine’s physical operation (as a belt-driven supercharger would be), the electric compressor provides a flexible and adaptable design that Honda can incorporate into the engine layout with fewer constraints.

Mass Centralization

By choosing an electric compressor over a traditional turbocharger or supercharger, Honda’s engineers also eliminate the need for an intercooler—a component that cools the compressed air, as needed in high-heat turbo or supercharger systems. Without an intercooler, the engine remains more compact, contributing to what’s known as “mass centralization.”

Mass centralization involves placing the engine’s weight and critical components as close to the center of the bike as possible. This design choice helps improve handling, making the bike feel balanced and responsive while riding.

Power Delivery and Ride Experience

Altogether, this engine layout, electric compressor, and compact design are intended to create a high-torque, responsive ride with smooth power delivery. The V3’s instant torque at lower revs and balanced setup promise a ride that’s both powerful and manageable, which should appeal to both everyday riders and those who seek a more performance-oriented experience.

This mechanism allows Honda to create an engine that’s compact, high-performing, and suited for larger displacement motorcycles without compromising on torque or handling.

History

The Honda V3 engine, for those of us intrigued by unique motorcycle engineering, has always been a fascinating piece of machinery. Essentially, it’s a V engine layout with an unusual twist—two cylinders on one side and a single cylinder on the other. While rare, this setup has mostly appeared in two-stroke engines, especially in motorcycles built for the intense demands of Grand Prix racing.

The story of the V3 engine goes back to 1955 with the DKW 350, marking its first appearance in racing. Later, in 1968, Suzuki created the RP68, a 50 cc V3 intended to compete that season, but a sudden rule change forced the bike out of contention, as only single-cylinder engines were allowed in that class.

Honda breathed new life into the V3 layout in the 1980s with the NS500/NSR500, used in Grand Prix racing from 1982 to 1984. The V3 design also found its way into Honda’s production models, like the MVX250F in 1983-84 and the NS400R from 1985 to 1987, adding a dose of racing DNA to sport bikes. Recently, in November 2024, Honda showcased a prototype V3 engine with an electric supercharger, signaling yet another evolution for this layout.

There’s also an interesting cousin to the V3 called the W3 engine, which has a distinct layout all three cylinders are arranged in a single plane but aren’t grouped into banks. This layout powered the Anzani engine from 1905 to 1915, used in early motorcycles and even aircraft. For anyone passionate about engine history, the V3 and its relatives offer a unique look at creative engine design over the years.